Dexterous hand motor module: high-precision drive solution

As the core drive component of humanoid robot fingers, the dexterous hand motor module is becoming a key technology for transmission control due to its compact structure, high torque density and precise control performance. This article explains its types, specifications, application scenarios and selection points in detail to help companies match efficient solutions.

1. Dexterous hand motor type

• Brushless DC motor (BLDC): low noise, long life, suitable for continuous operation scenarios (such as collaborative robot finger joints), generally used in micro electric levers. Refer to B1023 (with inner chain)

• Coreless brushed/brushless servo motor: closed-loop control, fast dynamic response, mostly used for force feedback dexterous hands, and this solution is generally used for those who pursue precision and more degrees of freedom. Refer to B1049

• Brushless outer rotor motor: round flat structure, suitable for structural designs requiring short fingers, medium control accuracy, and larger output, refer to BO2015

2. Core Specifications

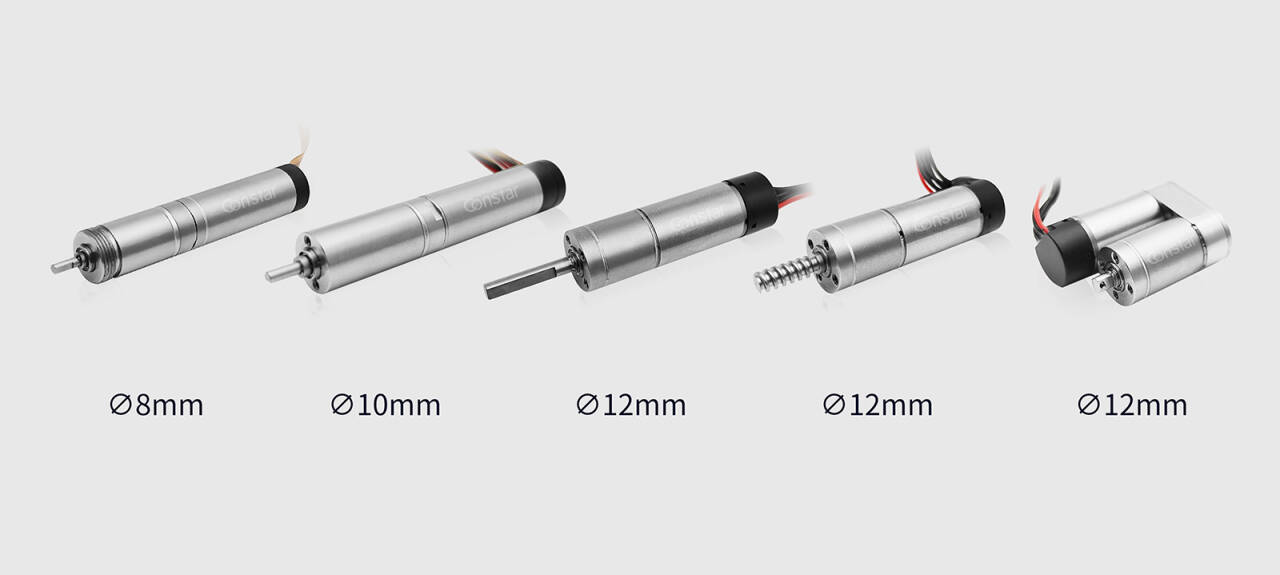

• Size: 8mm, 10mm, 12mm, 16mm in diameter. The mainstream market is currently focusing on the 10mm solution.

• Torque: The overall output of the motor is about 30-50mNm. The torque of different gearbox reduction ratios is different.

• Speed: 200~600 RPM under load. Some models support low-speed high-torque mode.

3. High-precision control

• Drive control: realize closed-loop control, communication protocol supports CANopen and Modbus.

• Encoder resolution: 16-1024, encoder (PCBA solution), incremental, absolute SSI/SPI protocol. 14-16 bit absolute encoder.

• Force control algorithm: current loop + impedance control, simulates the flexibility of human hand grip.

4. Typical application scenarios

• Humanoid robots: dexterous hands with different degrees of freedom, human-like finger joints, and support for adaptive adjustment of grasping force.

• Industrial automation execution: electronic component assembly, precision testing line.

• Bionic prosthesis: It realizes motion intention recognition through technologies such as electromyographic signals and brain-computer interfaces, and completes precise motion simulation with components such as micromotors.

5. Supplier selection suggestions

• Brand and scale: manufacturers with at least 10 years of experience in developing hollow cup motors and brushless motors.

• Customization capabilities: the number and titles of development engineers, and the project trial matching experience of application engineers.

• Certification system: the factory has a complete quality system, ISO9001\16949\13485\14001\45001, etc.

• Mass production capabilities: the number of factories, scale, and degree of automation of production lines.

• Technical support: the ability to customize motors and develop drive control programs.

The above points are the information that Constar motion has sorted out from several customers in multiple dexterous hand motor module projects. We hope it will be helpful to friends with the same needs. You can also contact us to ask existing solutions for selection reference.

Related products

- 0755-27351975

- 407943534

-

- 0755-27351975