PRODUCT

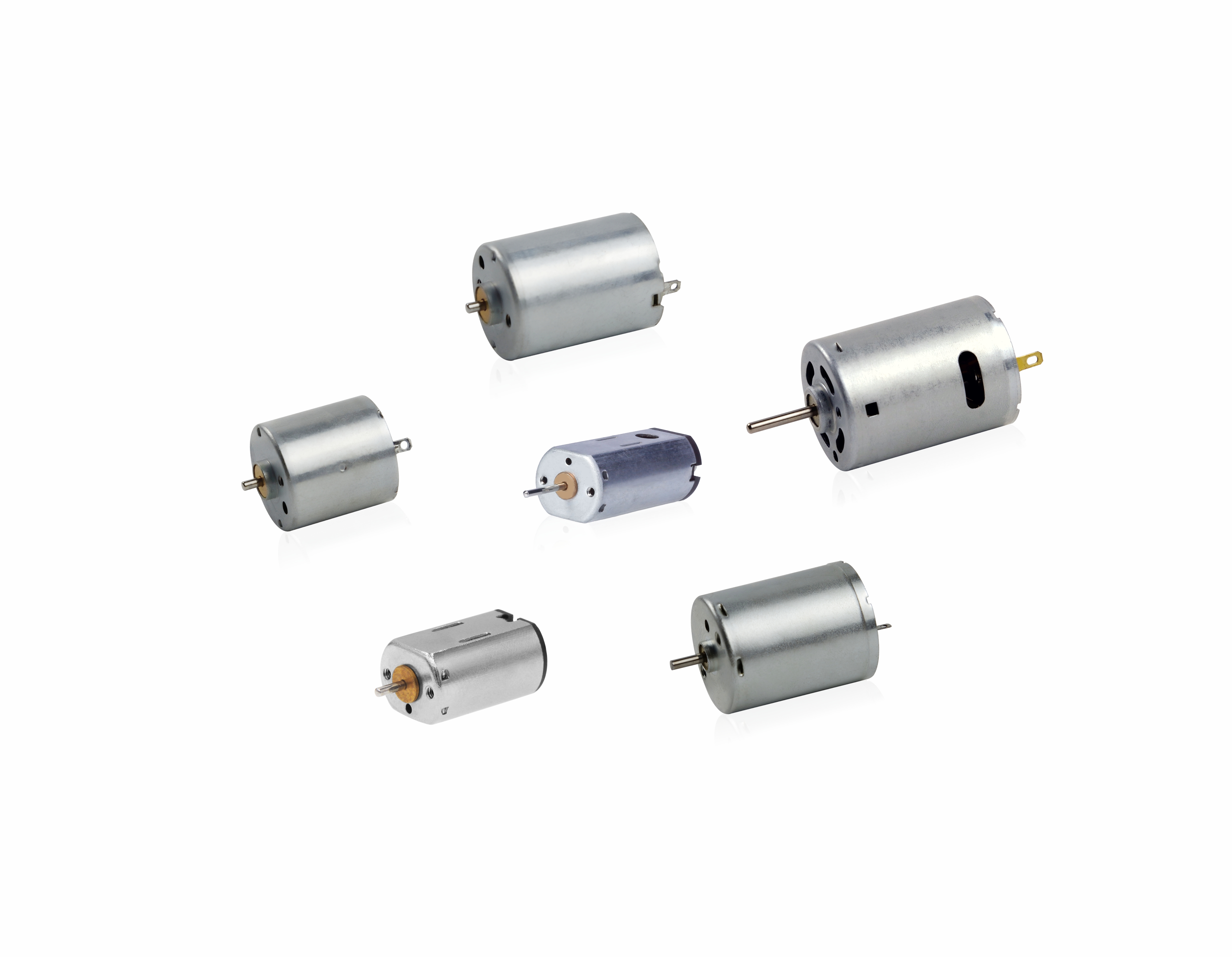

Through innovation and customization, we offer a wide range of micro motor products that precisely meet

your transmission needs and deliver outstanding performance for your applications.

Precision DC coreless motors adopt an ironless winding structure. Due to symmetrical windings, the motor features minimal vibration and smooth operation. The integrated design of windings, commutator and motor shaft results in low rotational inertia, high speed, excellent efficiency, reduced electromagnetic interference and extended service life. With linear output characteristics, they offer convenient speed regulation and outstanding servo performance. The use of high-performance NdFeB rare-earth magnets enables compact dimensions.

For low-power applications, motors with precious metal commutators are recommended, while carbon brush commutator versions are available for higher power output and longer service life requirements. These products are widely used in medical equipment, precision instruments, robotics and industrial applications.

Constar brushless motors overcome the critical weakness of traditional brushed DC motors—contact-based mechanical commutation—delivering extended service life. Their superior performance includes: high reliability, high rotational speed, compact size, strong overload capacity, minimal electromagnetic interference, low noise, smooth speed regulation, and robust operation in harsh environments.

It belongs to the category of permanent magnet synchronous motors and serves as the active torque and speed generation component of traditional motors, but lacks a shaft, bearings, housing, or end brackets. A frameless motor consists of only two parts: the rotor and the stator. The rotor, typically the inner component, is a rotating steel ring assembly with permanent magnets, mounted directly onto the machine shaft. The stator, the outer component, features steel laminations and copper windings around its teeth, generating electromagnetic forces and designed to be tightly installed within the machine housing.

Featuring an ultra-compact integrated design with minimal size and weight, it adapts to confined space installations. Equipped with a high-precision encoder and closed-loop feedback system, it delivers precise positioning, wide speed regulation range, and high instantaneous torque density. Integrated stepless speed control algorithm balances high performance with low energy consumption. The all-metal gearbox structure with high protection grade ensures vibration resistance, wear durability, and extended service life. Suitable for collaborative robot joints, medical devices, precision instruments, and other applications, providing core drive for lightweight, high-dynamic equipment.

Constar drive motors can be equipped with various precision gear reducers of different structures and reduction ratios to meet high-torque, low-speed application requirements. These products feature compact size, high reduction ratio, low speed, and high torque, making them widely applicable in medical devices, precision instruments, industrial equipment, security systems, imaging products, personal care devices, and high-end toys.

DC Iron-Core Motors feature coils wound on iron cores, delivering stable and reliable performance. For high-load, long-life applications, we recommend carbon brush structures.

Drive Series are widely used in:Security systems、Small electronic devices、RC aircraft toys、Personal care products、Portable tools.Vibration Series are extensively applied in:Communication devices、Healthcare equipment.

- 0755-27351975

- 407943534

-

- 0755-27351975