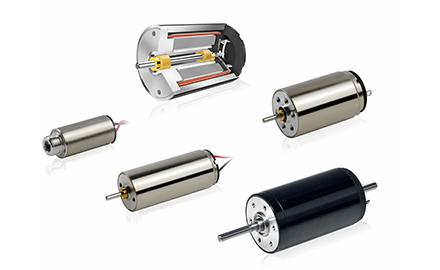

Motors

25 Years of Micro Motor Mastery: Precision-Tuned Solutions for Your Unique Motion Challenges

Applications

Powering Innovation Across High-Performance Applications: Reliable Motion Systems Engineered for Excellence

Medical Equipment

Medical Equipment

With the advancement of science and technology and the continuous improvement of medical needs, the application of motors in medical devices is developing in a more intelligent, miniaturized and efficient direction.

Radiation Therapy Equipment Orthopedic Power Ventilator

View Details

Automobile

Automobile

Micro motors have already played an important role in traditional automotive applications. There are dozens of micro motors in an ordinary car.

Car Seat Rotatable in-car display adjustment Automotive LiDAR

View Details

Robotice

Robotice

In the not-too-distant future, robotic technology will develop at an unprecedented speed and reshape our world. They are profoundly changing every corner of human society...

Floor washer Autonomous delivery vehicle (ADV) Robotic arm

View Details

Industrial Automation

Industrial Automation

Micromotors are an indispensable part of industrial automation, with wide applications and far-reaching influence.

Electric strapping machine Valve actuator Laser scanning

View Details

Other

Other

We use micro motor technology and professional application experience to meet the needs of various drive control applications.

5G Communication Wind Power Generation Aerospace

View Details

Six-Step Journey to Your Custom Motor

Requirement Discovery & Analysis

Requirement Discovery & Analysis

Understand key information such as motor application scenarios, performance requirements (such as power, speed, torque, control, etc.), size restrictions, and working environment conditions (such as temperature, humidity, protection level).

Technical Feasibility Assessment

Technical Feasibility Assessment

Based on customer requirements, the technical team conducts technical analysis to evaluate whether existing products can meet the needs or whether development and customization are needed. Provide a preliminary motor plan and make a cost estimate.

Solution Development & Approval

Solution Development & Approval

Introduce the preliminary plan to the customer in detail, including technical details, expected performance, cost budget, etc., and listen to feedback and modification opinions. Make necessary adjustments and optimizations to the plan to ensure that the final plan fully meets the customer's expectations and needs. Sign a technical agreement after reaching a consensus and confirming the plan.

Solution Development & Approval

Make a prototype according to the confirmed plan, test and verify the performance and provide a test report. The customer receives the sample and assembles it according to their project requirements for confirmation.

Prototype Validation Testing

Prototype Validation Testing

Make a prototype according to the confirmed plan, test and verify the performance and provide a test report. The customer receives the sample and assembles it according to their project requirements for confirmation.

Pilot Production Run

Pilot Production Run

After prototype testing and confirmation, the production process will be optimized and improved as necessary to improve production efficiency and product quality. Carry out small batch production to verify the optimized production process and product quality stability. Customers inspect products produced in small batches to ensure that they meet actual needs.

Full-Scale Manufacturing

Full-Scale Manufacturing

After small batch trial production is confirmed, preparations for large-scale production will be carried out, including raw material procurement, tooling design, equipment configuration, work card production, production line layout, personnel training, etc. Start the formal mass production process, produce motors according to order requirements, and strictly control every aspect of the production process to ensure product quality.

01.Requirement Discovery & Analysis

Understand key information such as motor application scenarios, performance requirements (such as power, speed, torque, control, etc.), size restrictions, and working environment conditions (such as temperature, humidity, protection level).

02.Technical Feasibility Assessment

Based on customer requirements, the technical team conducts technical analysis to evaluate whether existing products can meet the needs or whether development and customization are needed. Provide a preliminary motor plan and make a cost estimate.

03.Solution Development & Approval

Introduce the preliminary plan to the customer in detail, including technical details, expected performance, cost budget, etc., and listen to feedback and modification opinions. Make necessary adjustments and optimizations to the plan to ensure that the final plan fully meets the customer's expectations and needs. Sign a technical agreement after reaching a consensus and confirming the plan.

04.Prototype Validation Testing

Make a prototype according to the confirmed plan, test and verify the performance and provide a test report. The customer receives the sample and assembles it according to their project requirements for confirmation.

05.Pilot Production Run

After prototype testing and confirmation, the production process will be optimized and improved as necessary to improve production efficiency and product quality. Carry out small batch production to verify the optimized production process and product quality stability. Customers inspect products produced in small batches to ensure that they meet actual needs.

06.Full-Scale Manufacturing

After small batch trial production is confirmed, preparations for large-scale production will be carried out, including raw material procurement, tooling design, equipment configuration, work card production, production line layout, personnel training, etc. Start the formal mass production process, produce motors according to order requirements, and strictly control every aspect of the production process to ensure product quality.

About Constar

Rooted in heritage, driven by innovation – Engineering excellence in perpetual evolution.

R & D Strength

Customized Service

Superfine Manufacturing

Quality Assurance

News

- 0755-27351975

- 407943534

-

- 0755-27351975